Deployment and Assembly

Pre-stressed structures that dependably self-deploy when stowed for long periods will make efficient, lightweight flexural components used in gossamer deorbiting systems.

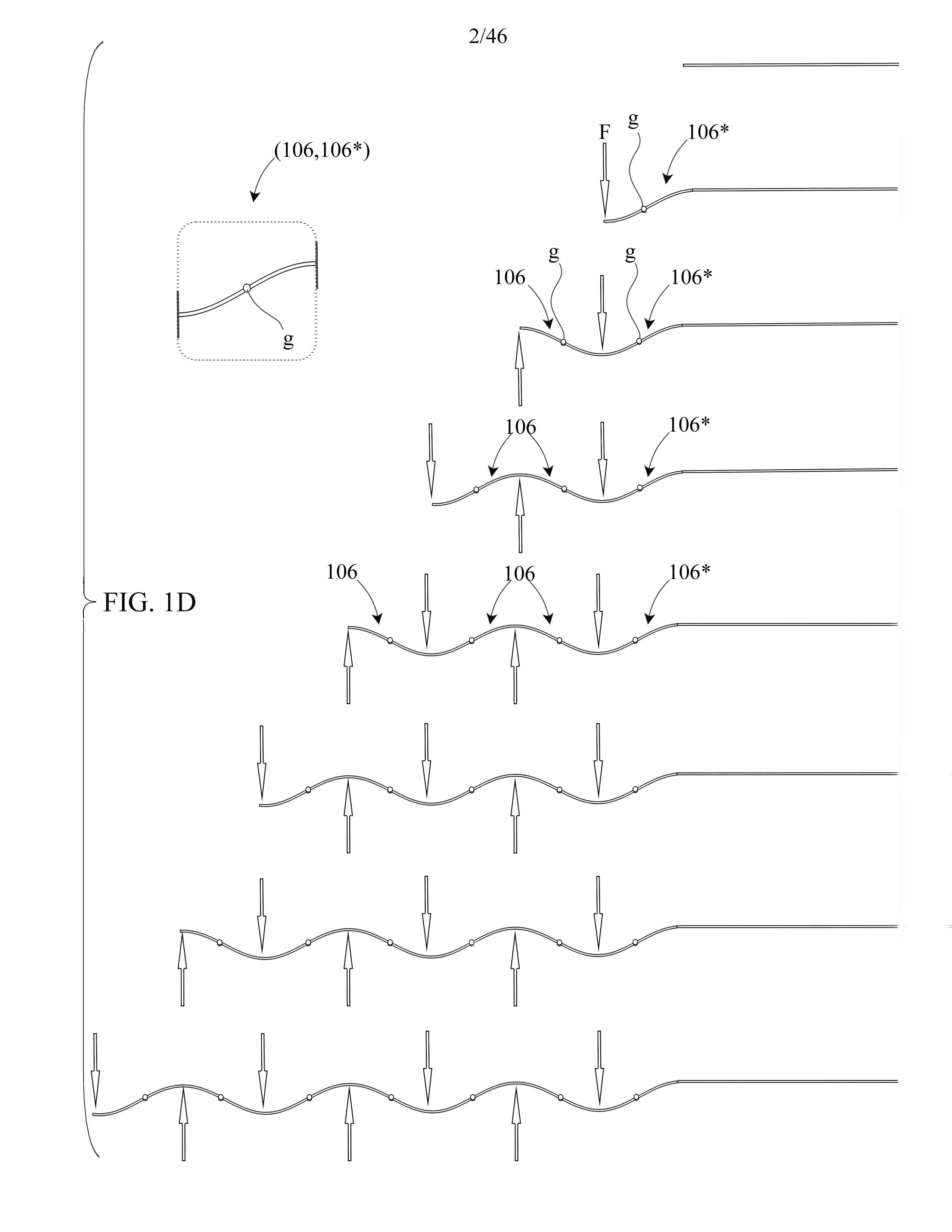

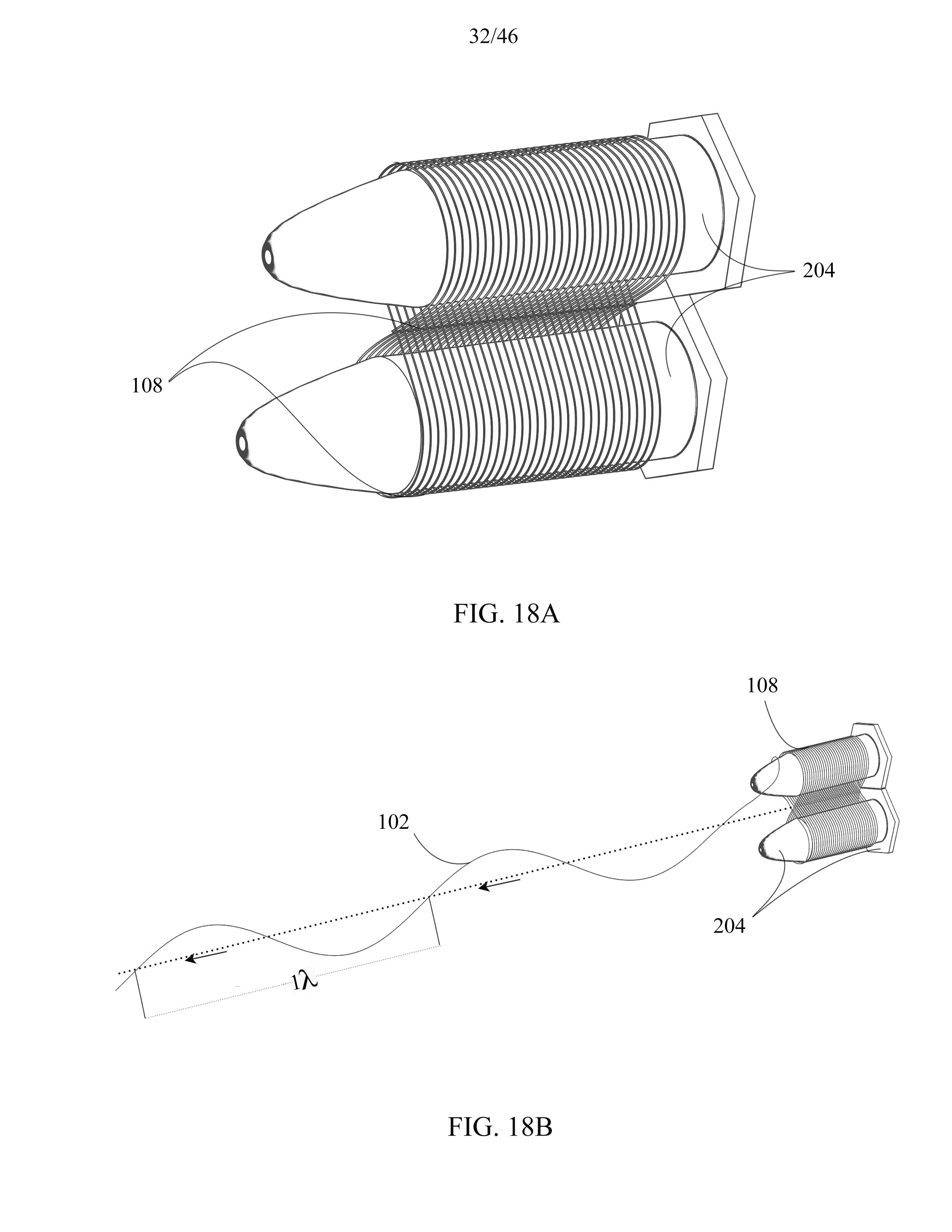

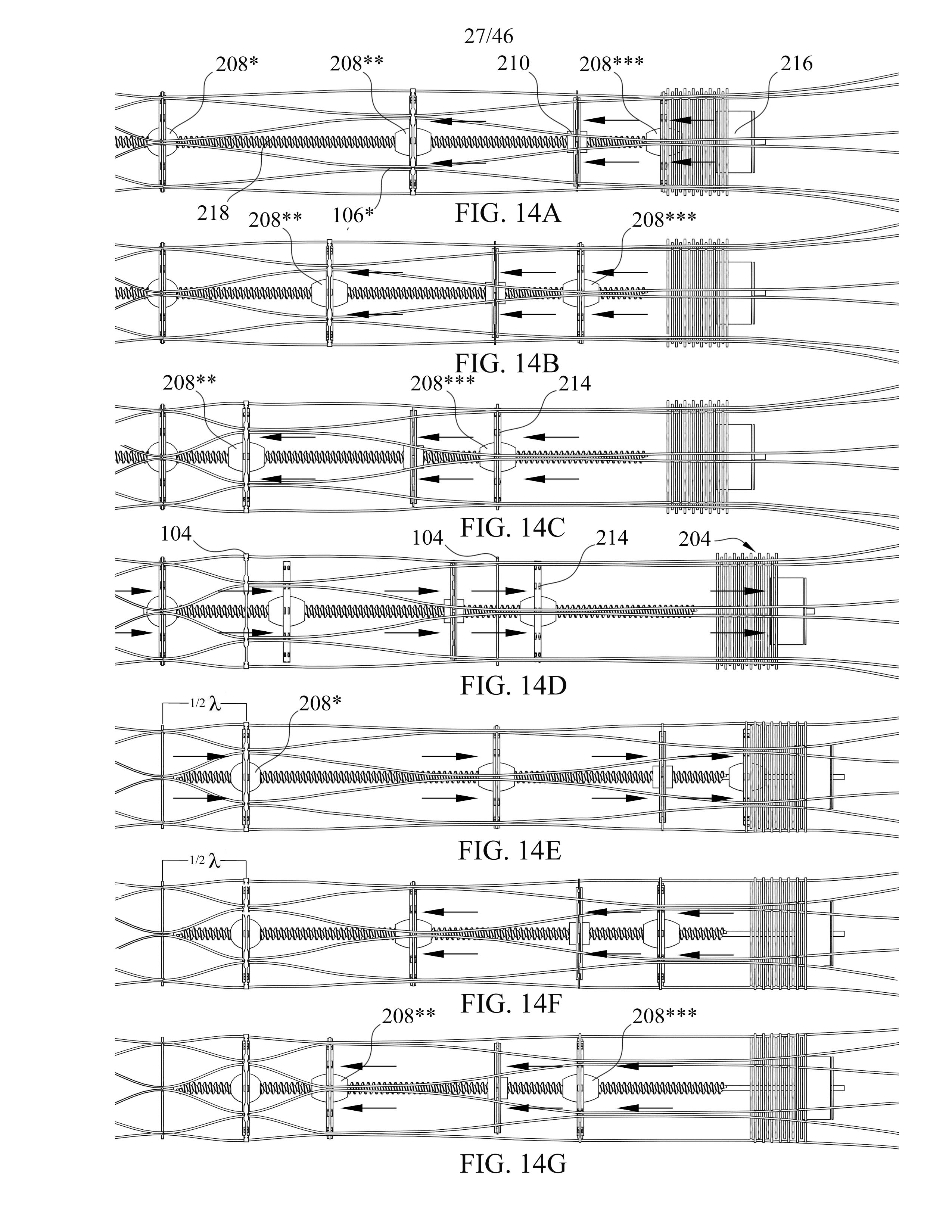

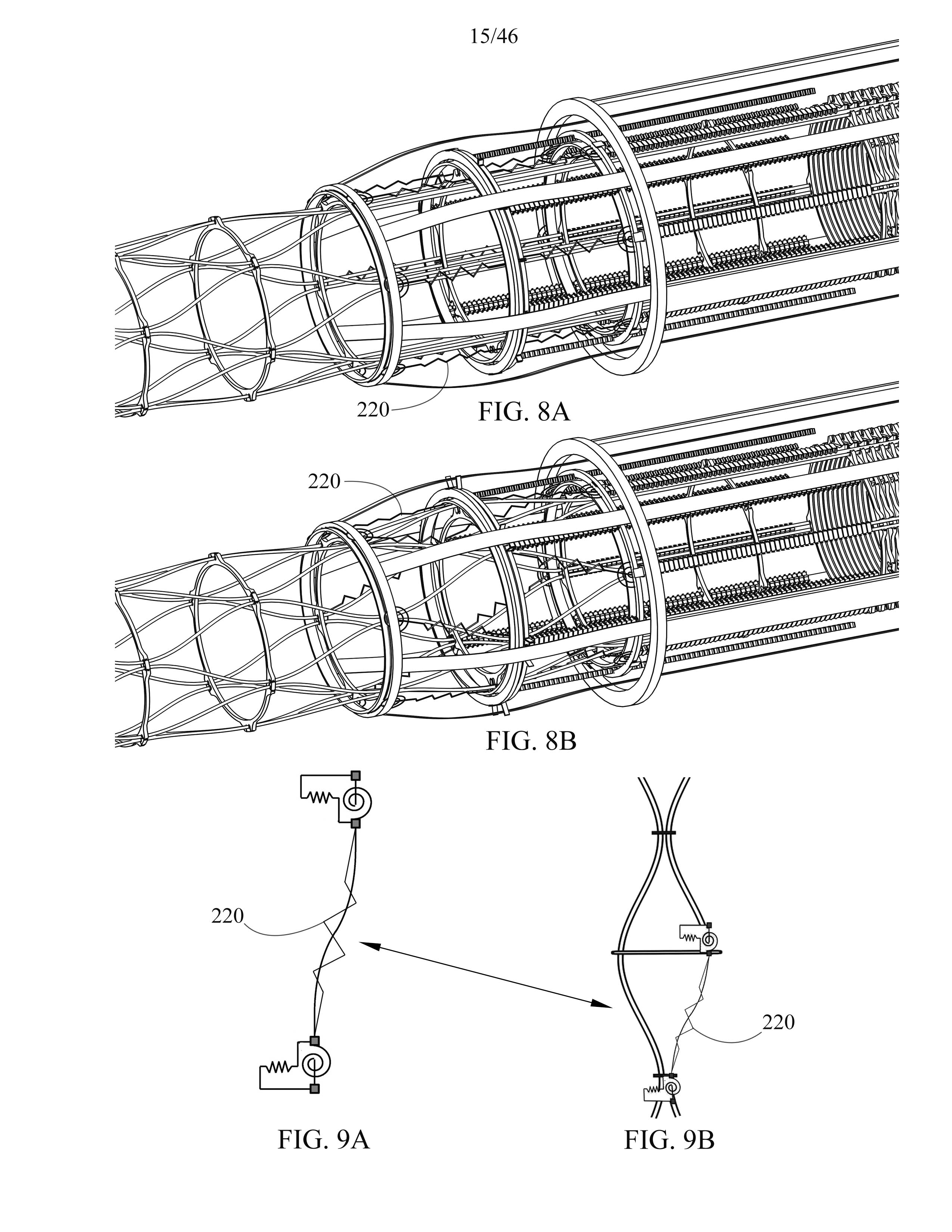

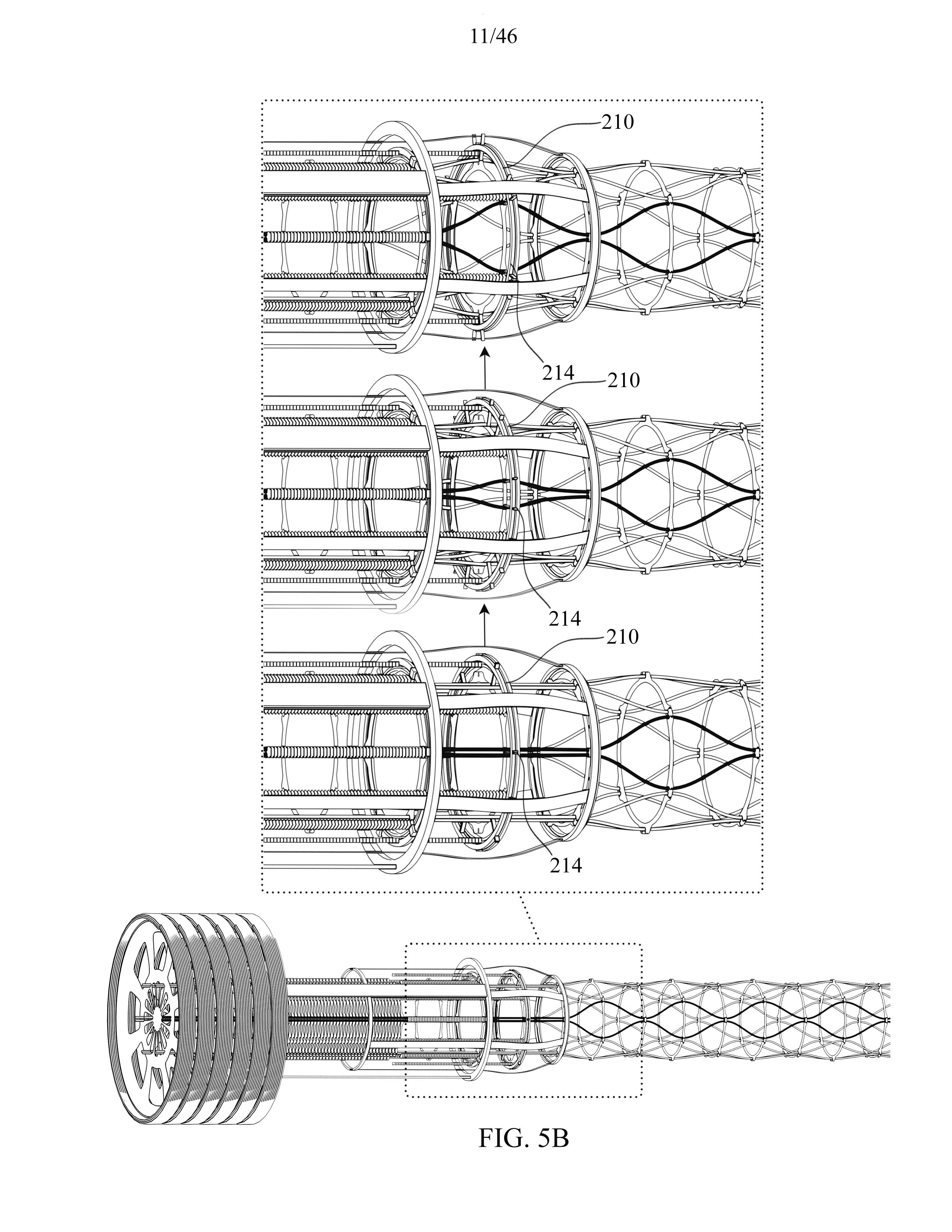

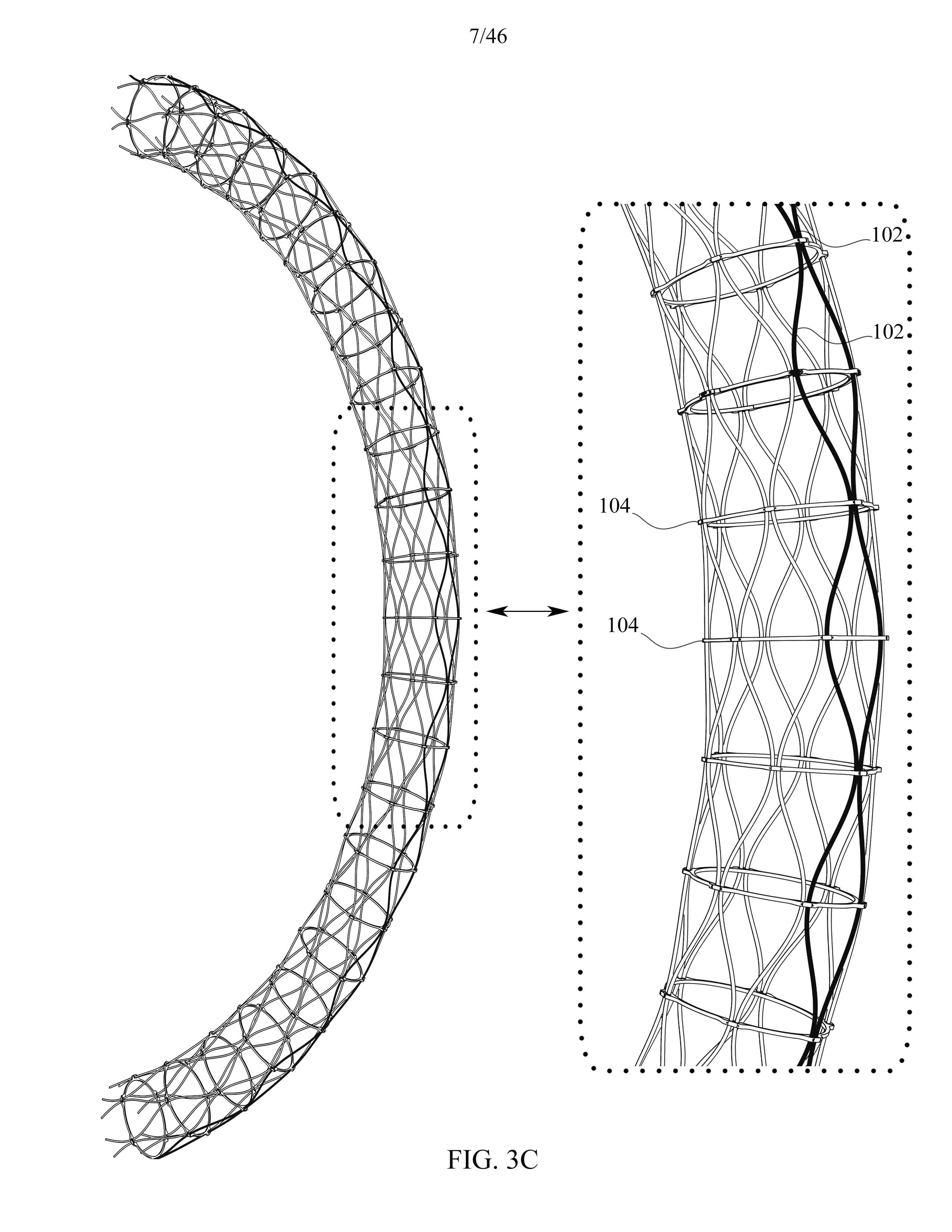

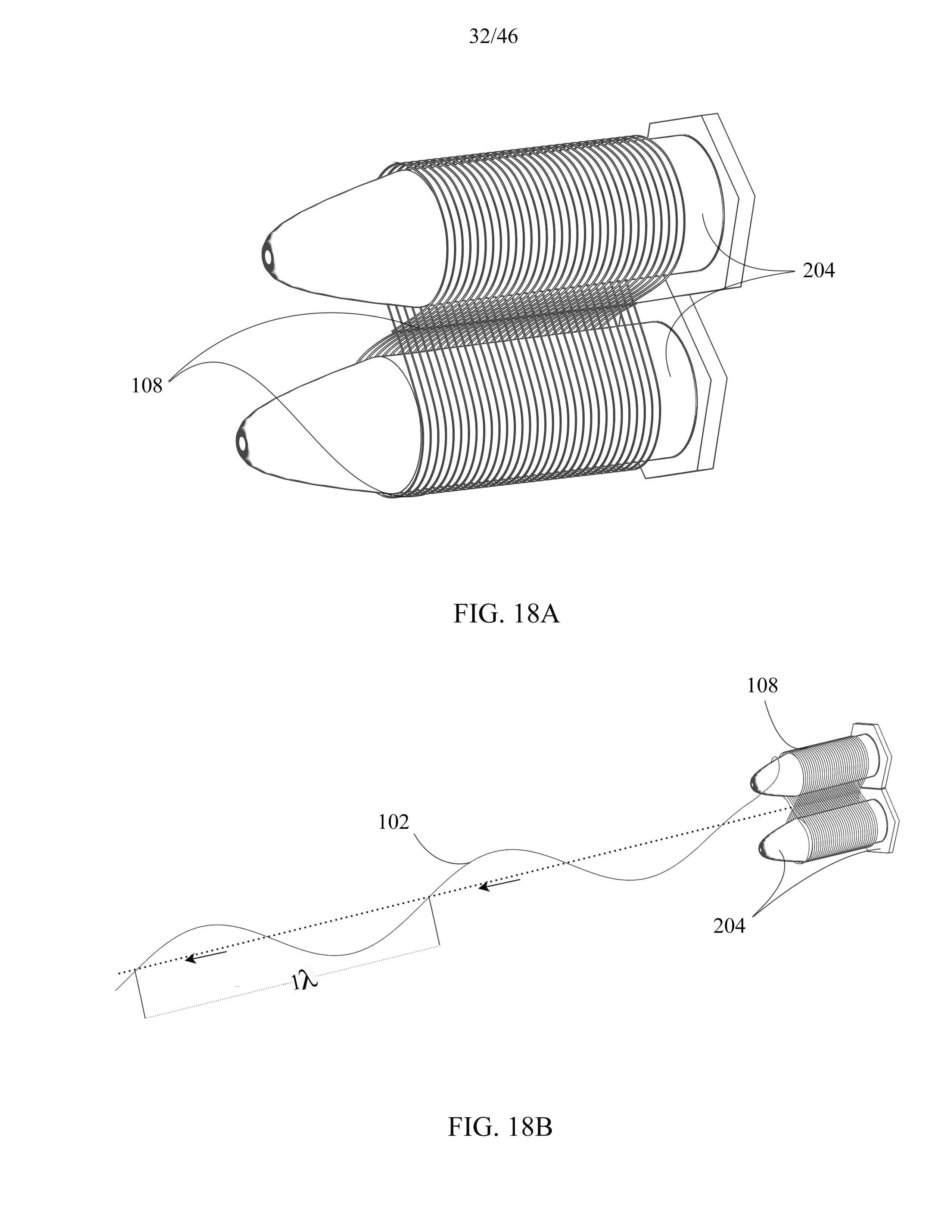

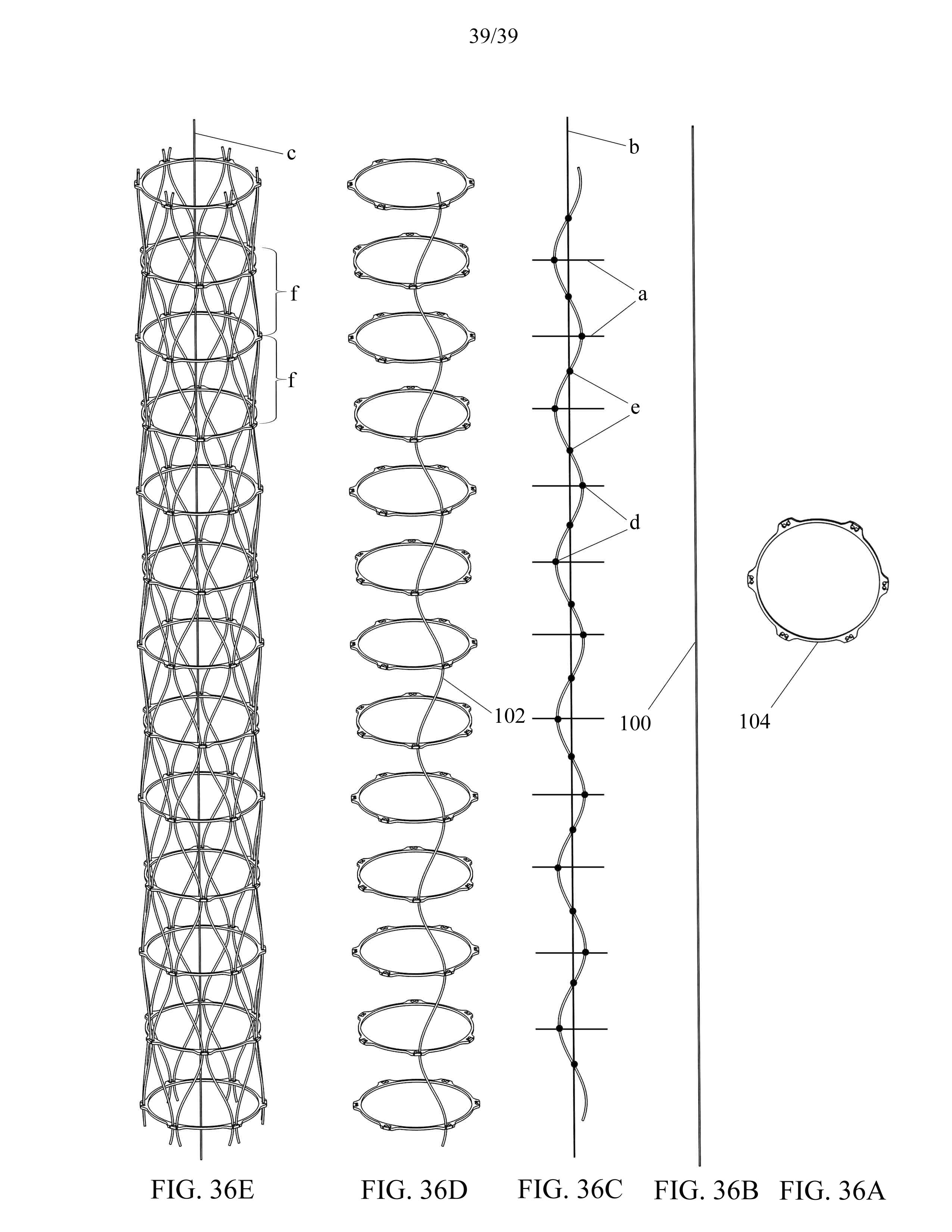

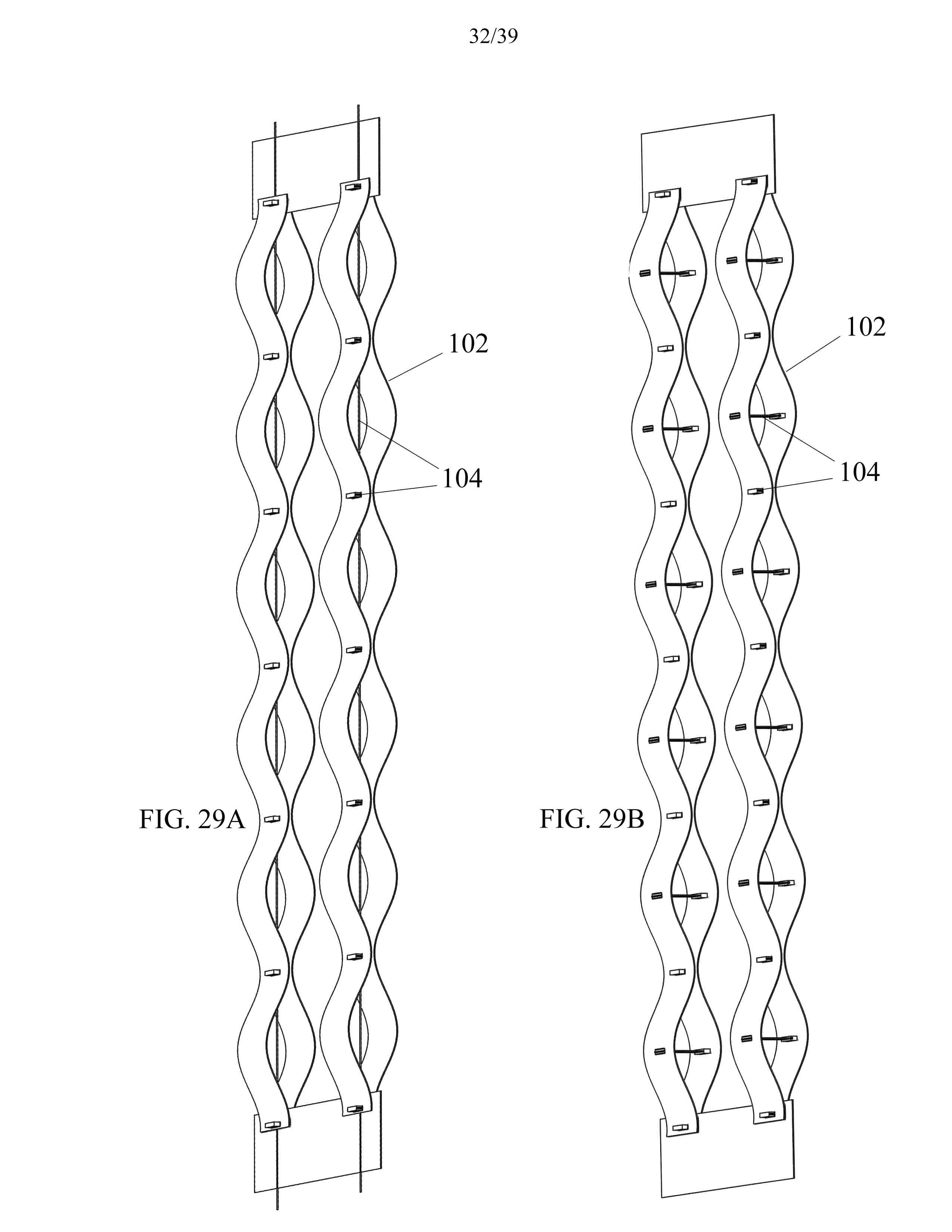

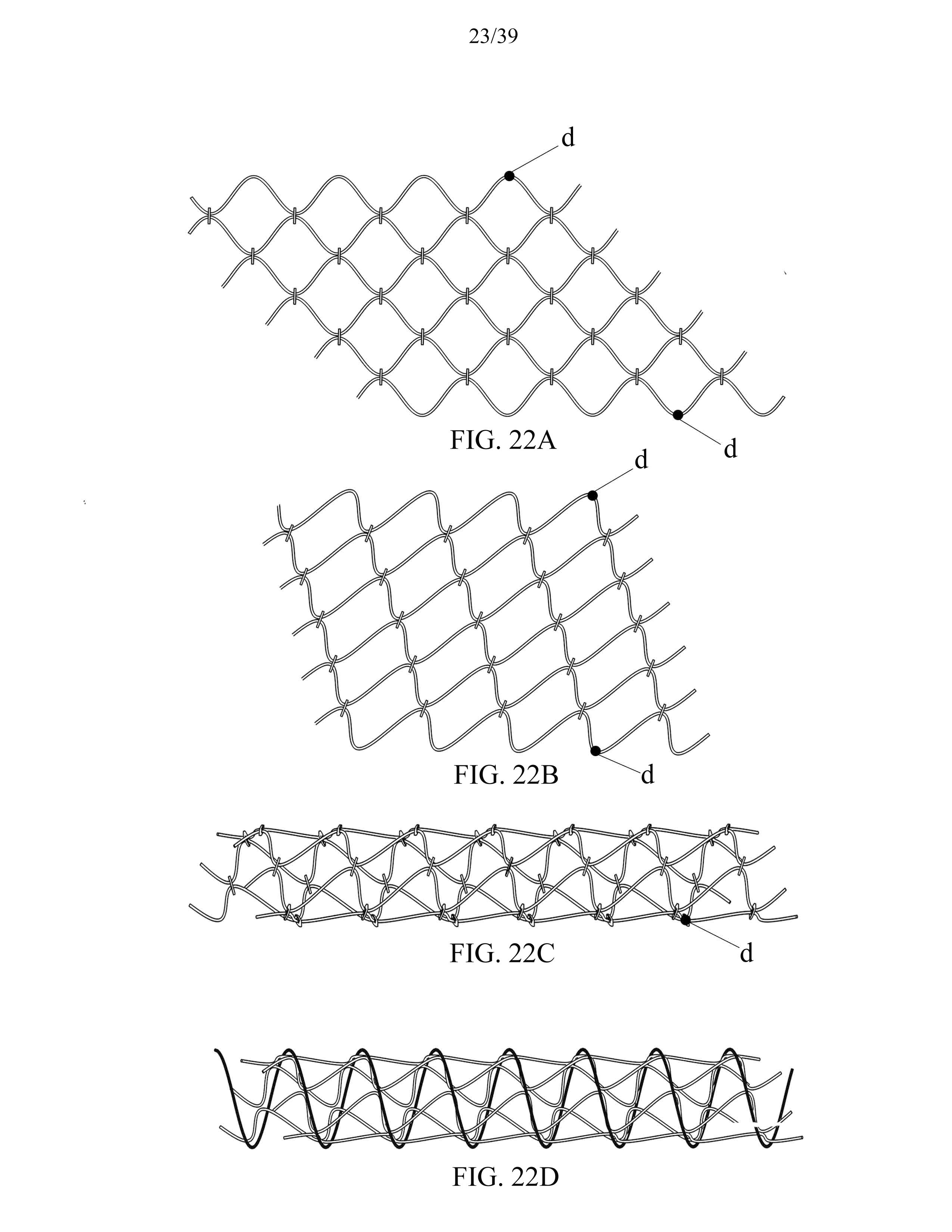

Flexure elements are flexures. They can be slender, they are flexible, deflected and form flexural regions between support members along the length of a sinusoidal member. Flexural regions are composed of one half of a wavelength (λ/2) and/or one wavelength (1λ) flexure elements/flexures. A flexural member is a sinusoidal shaped member that is formed from a relaxed material having elastic properties. The series of contiguous periodically deflected regions give the flexural member its stored elastic potential energy and sinusoidal shape.

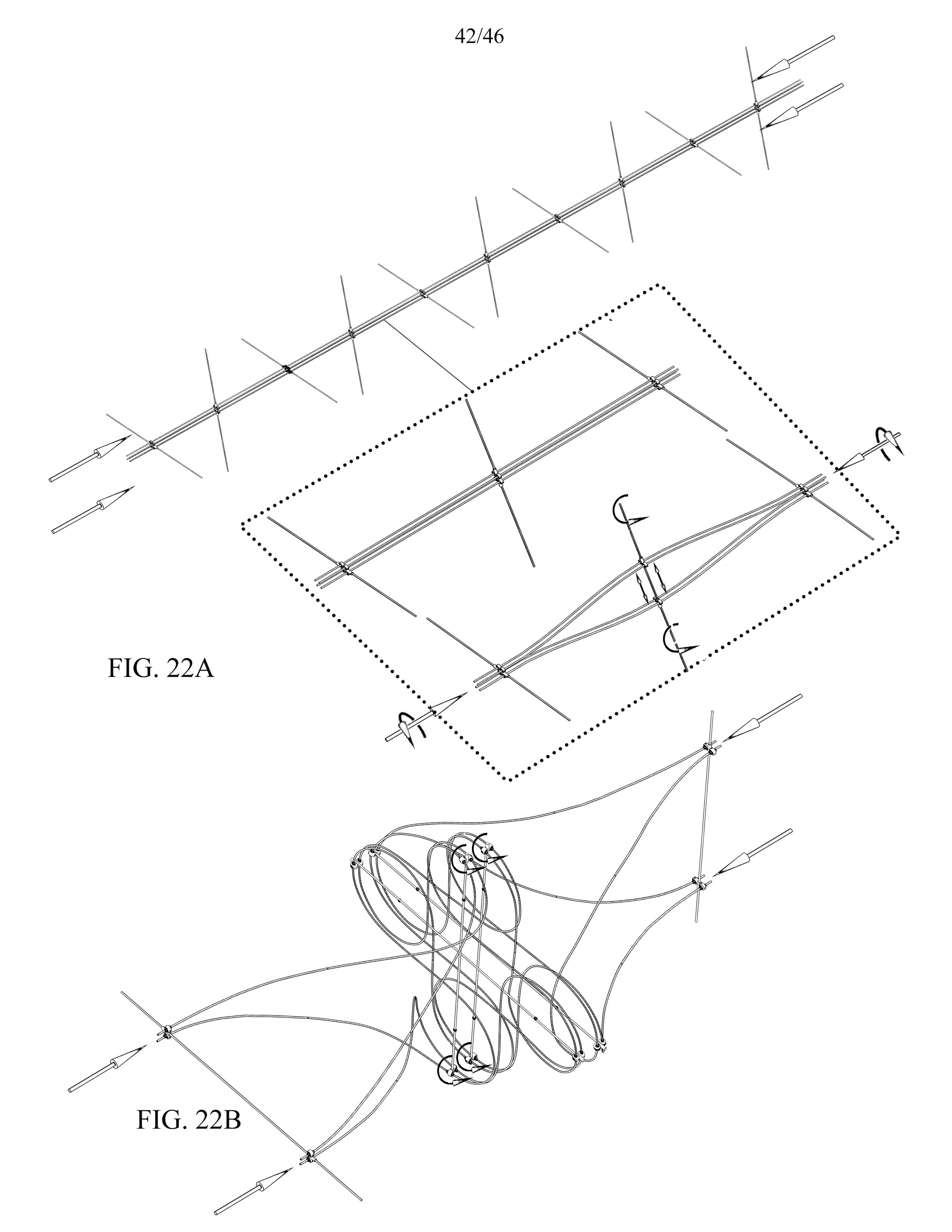

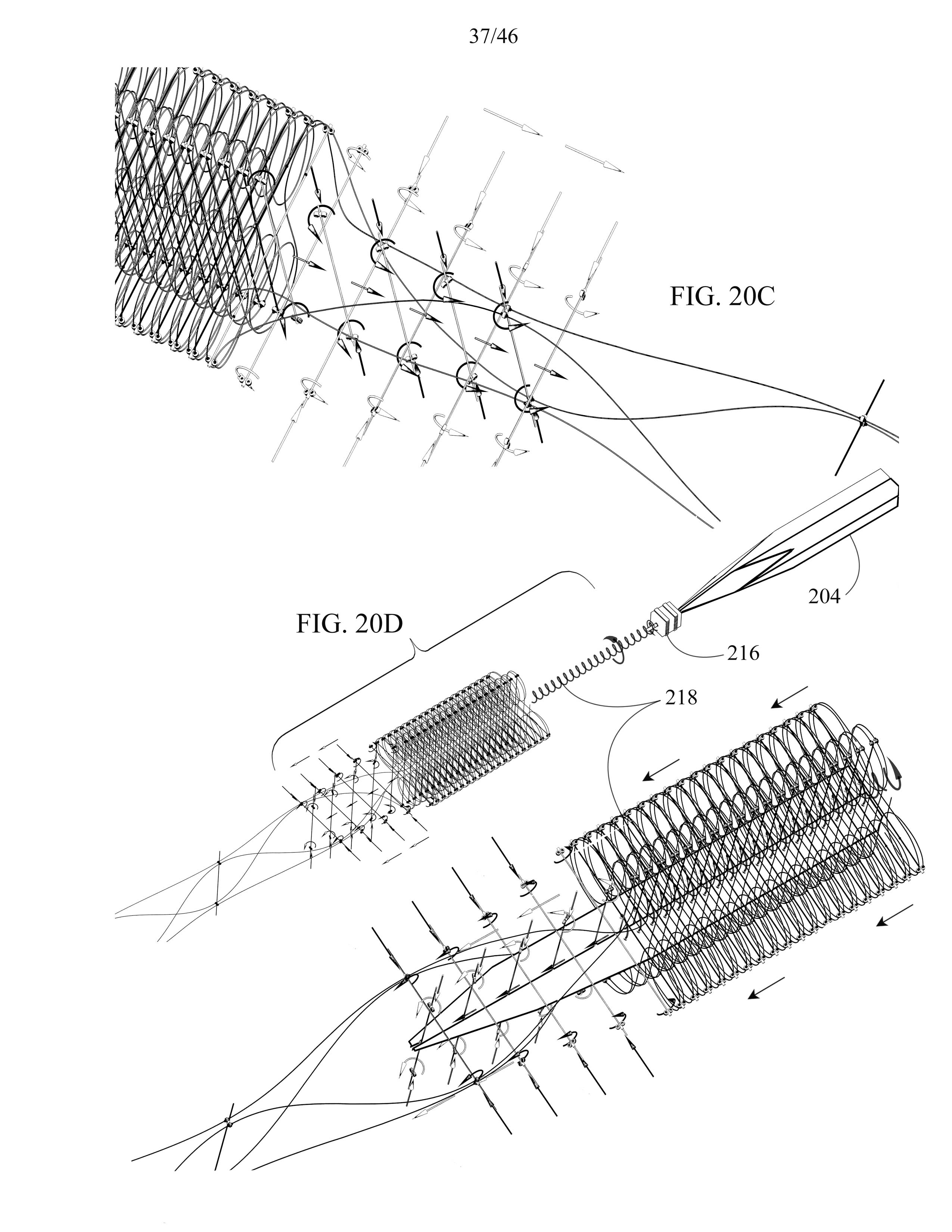

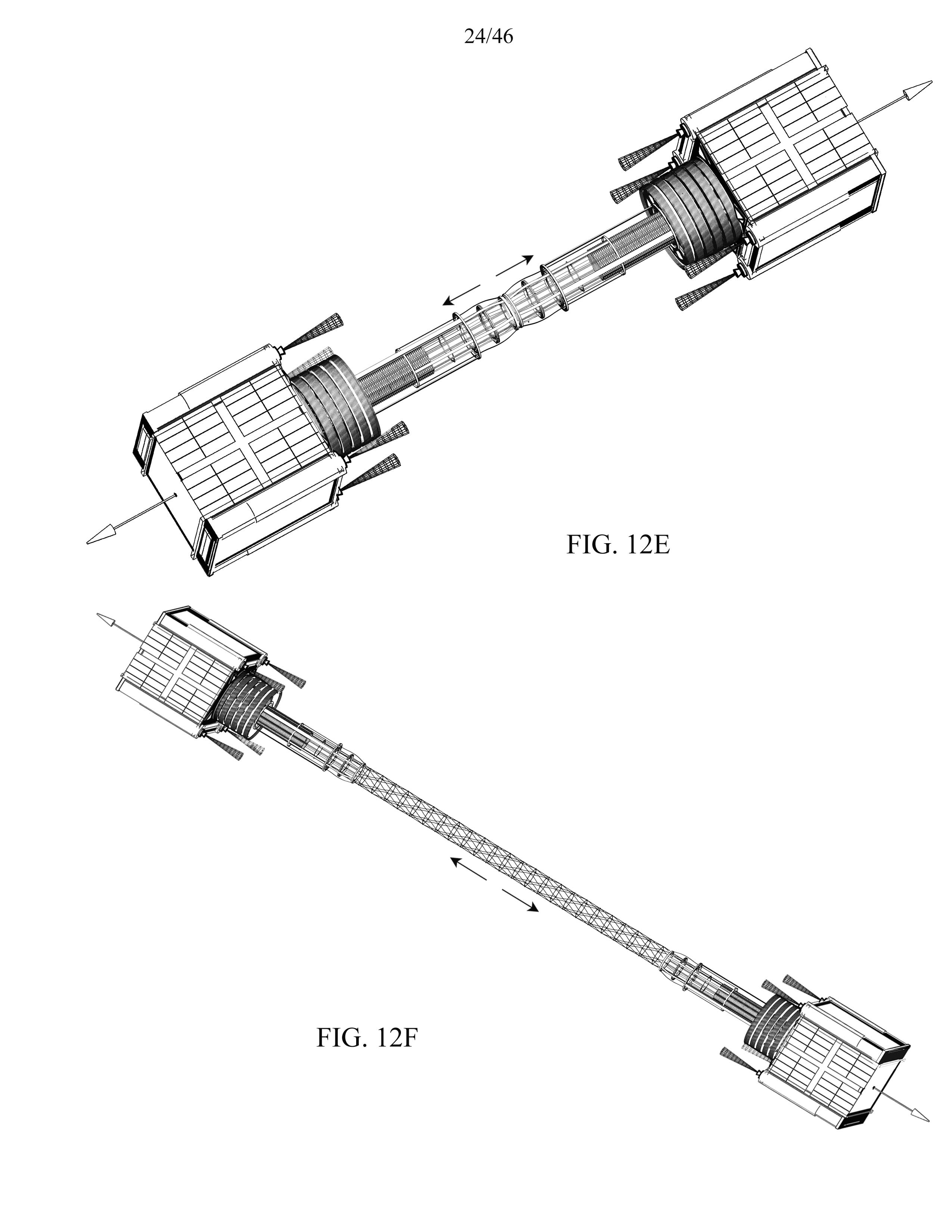

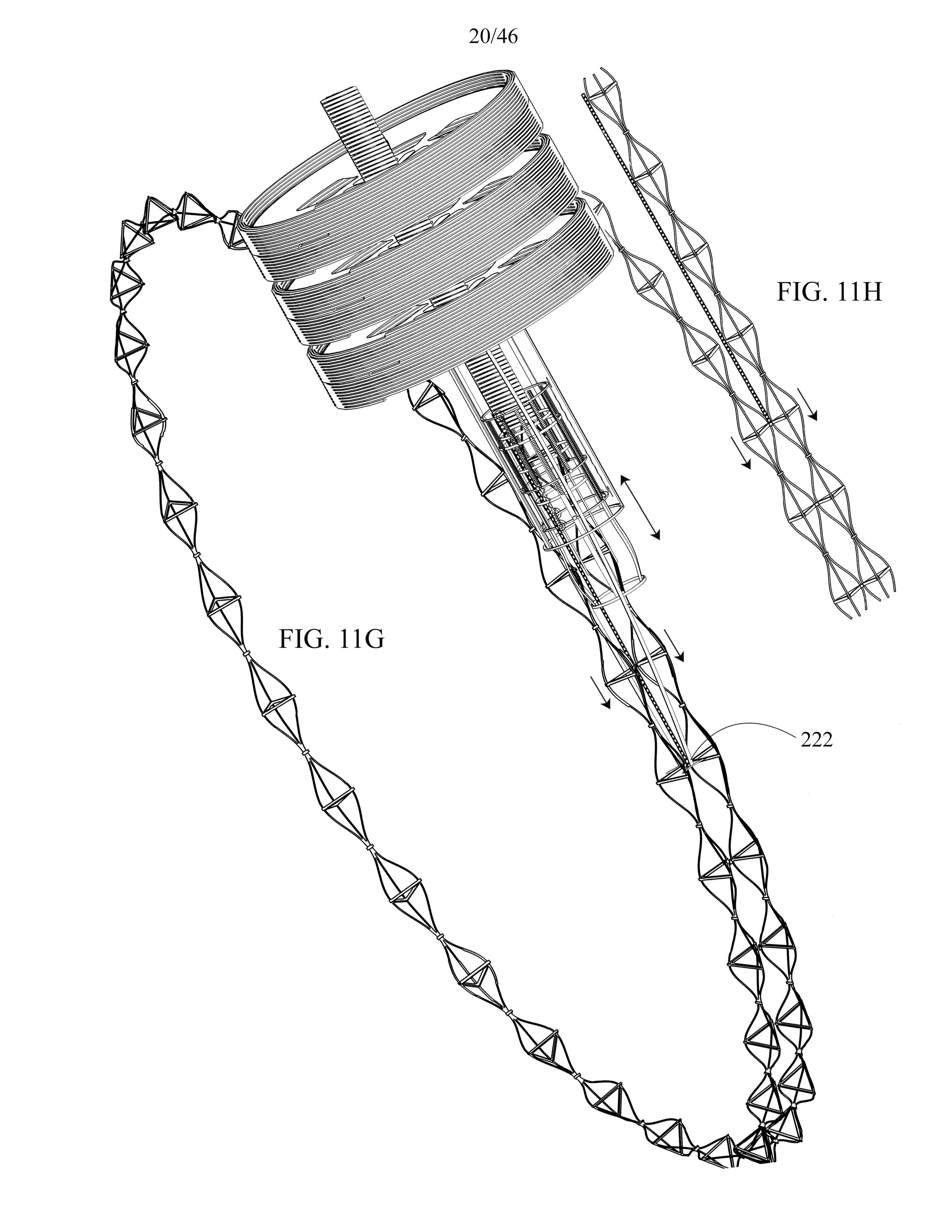

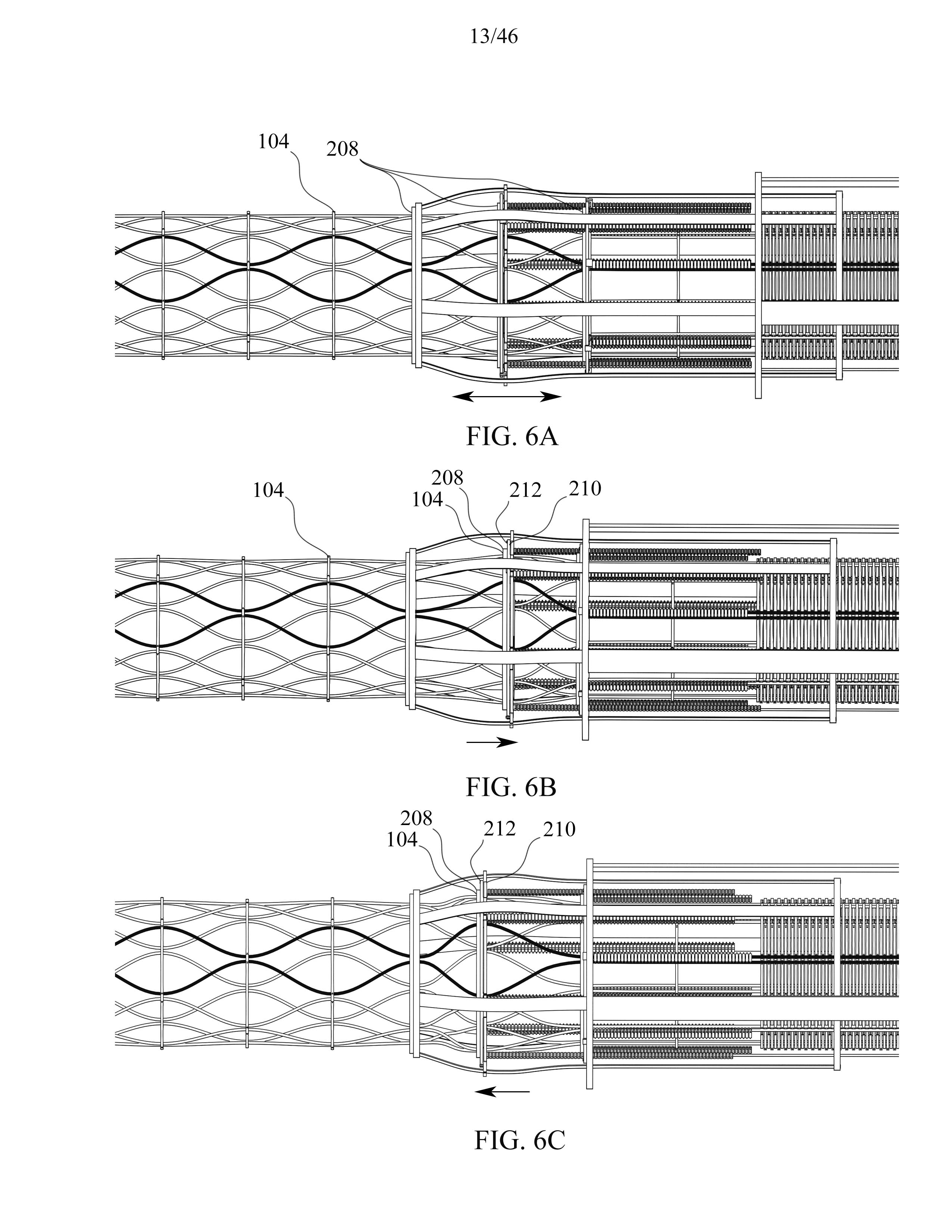

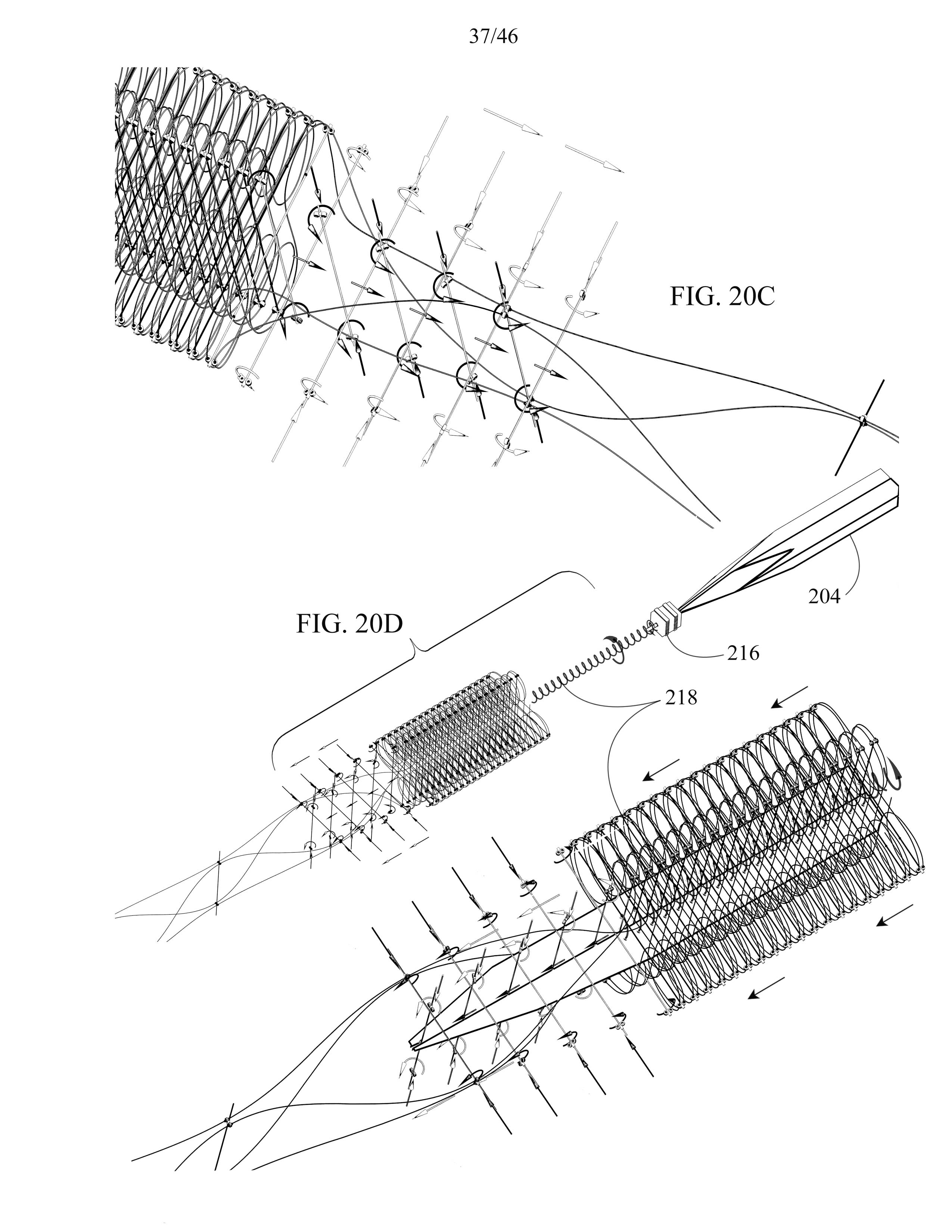

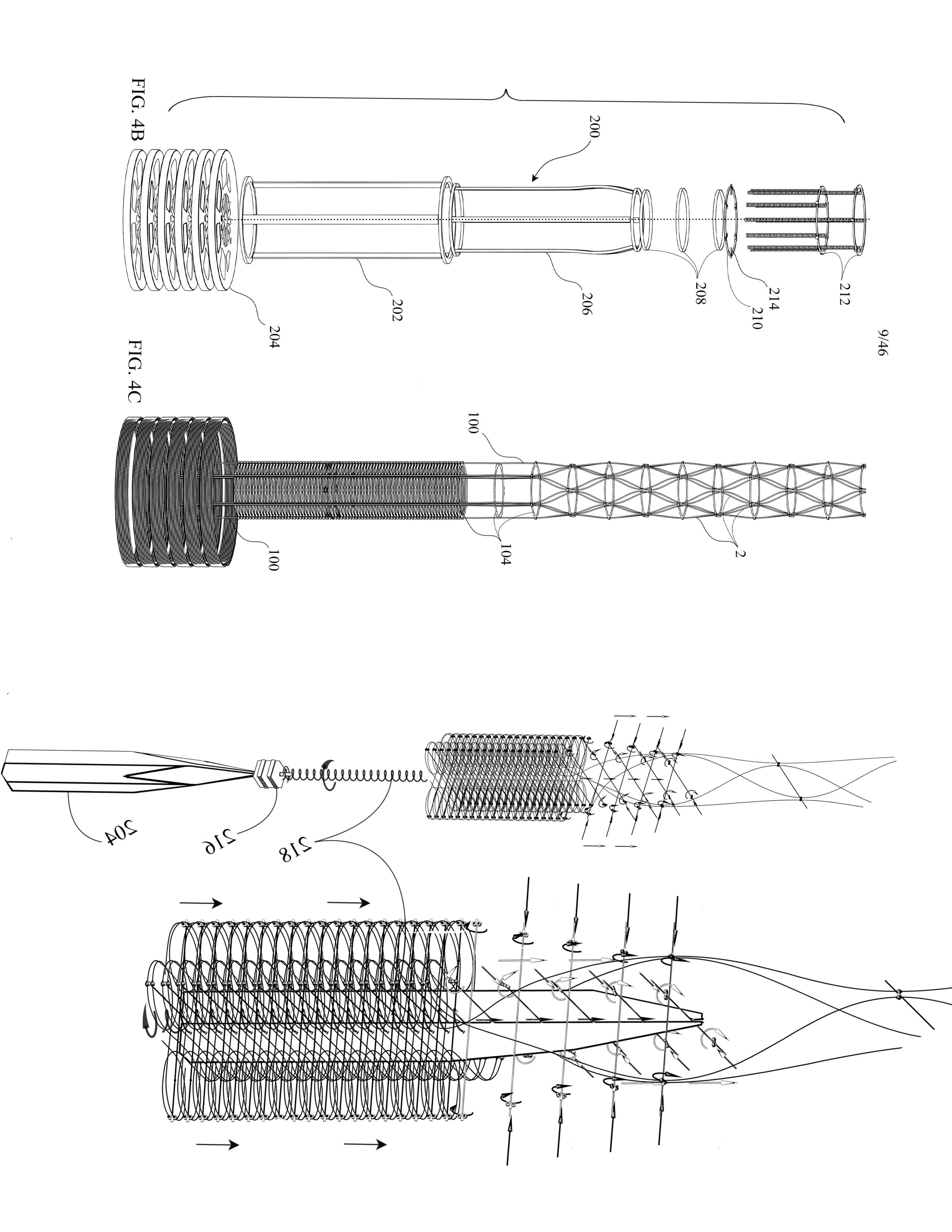

The extrusion of a structure is an assembly process and/or a deployment process. The act of extrusion alters material and structure by transitioning their form. The transition may involve a gain or loss of elastic potential energy. The extrusion of a structure acts by applying moments (or redirecting energy) to a structure or its components leading to a change in its form. The extrusion and resulting form transition may be a reversible process (i.e. reversible deployment).

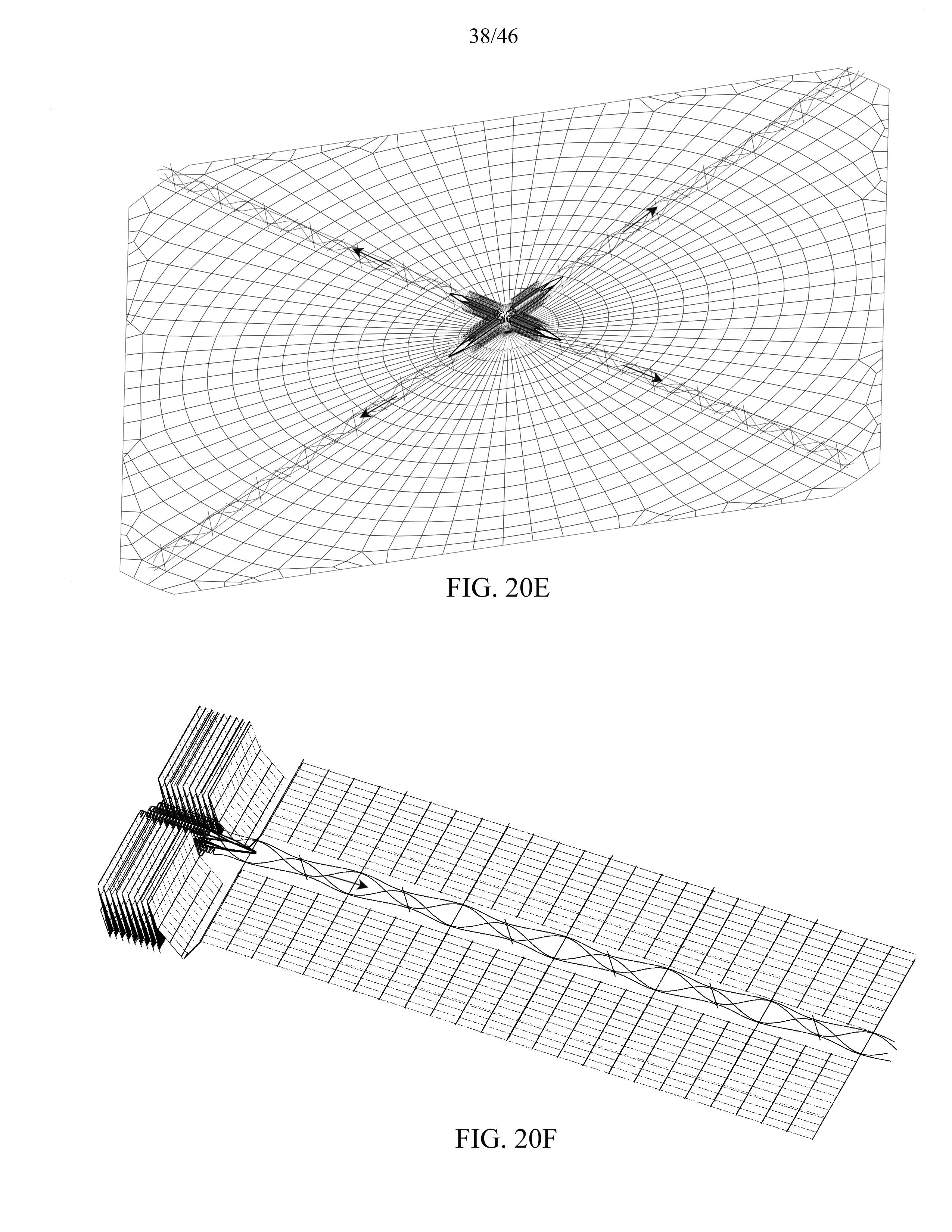

The machines and devices related to the automated assembly and/or deployment of these pre-stressed assemblies function to position, connect and orient a structure’s constituent parts. This level of control during assembly allows the structure’s distribution of internal stress to be modulated, and its structural and behavioral properties to be controlled. By controlling the structure’s distribution of internal stress in relation to the assembly’s centroid axis, the structure’s deflection characteristics can be predetermined and its secondary shape controlled.

The introduction of stress during assembly can improve a structure’s strength to weight ratio, its flexural performance and resilience along with its toughness. Concerns related to the longevity of pre-stressed structures formed from elastic materials due to stress relaxation and creep will not dissuade its future use. Given the trajectory of nano-composite material development, flexural pre-stressing will increasingly be used as a method of reliably enhancing the overall performance of a dynamic structure. The enhanced efficiency and performance brought about by flexural pre-stressing is particularly important to aerospace applications.

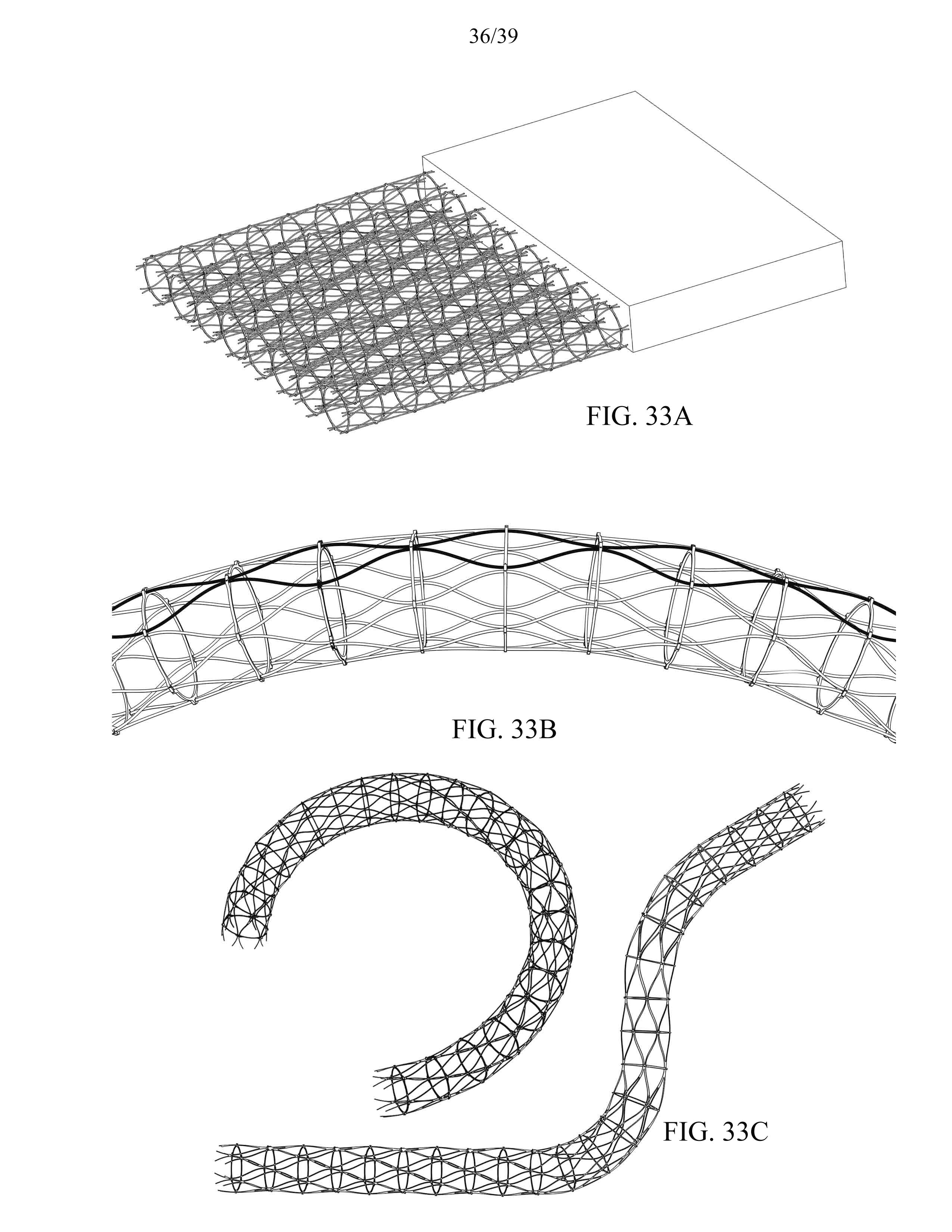

The manufacture of large truss systems used to support new space technologies like solar power supply constellations and large space structures used to support microwave antennae and mirrors are of great interest. Flexible trusses made of flexural members are better suited to form space structures than current ridged trusses because of their compact pre-deployment packaging in the launch vehicle and their ability to manage large elastic displacements experienced during operational and construction loads.

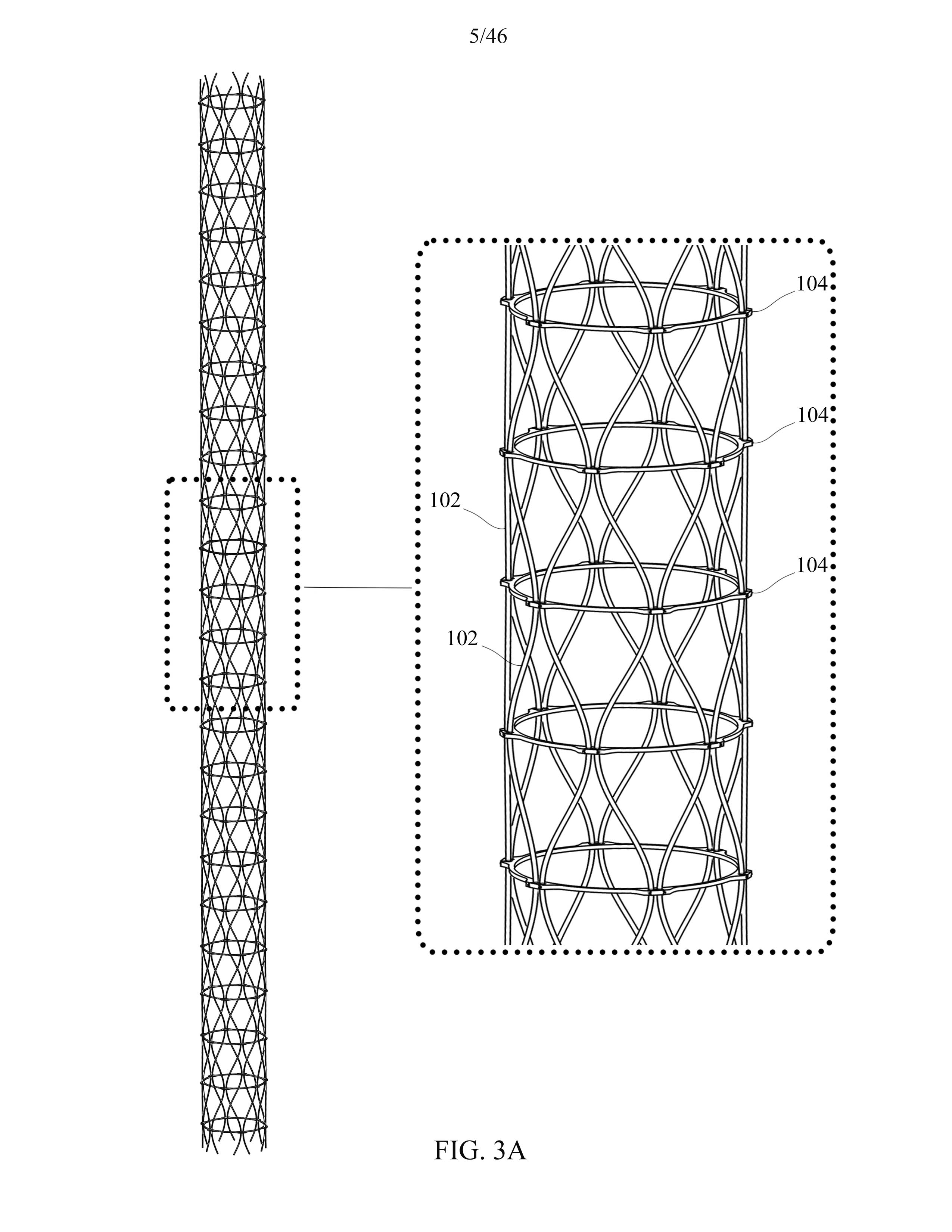

The individual flexure elements/flexures are organized sequentially and contiguously to form a sinusoidal shaped member from a single piece of material during assembly. That sinusoidal shaped member is a series of connected flexure elements/flexures; the flexures are delineated and held in an elastically deformed state by support members that are positioned at antinode regions along the sinusoidal shaped member’s length during assembly.

Bistable structures including those having snap-through properties (like those capable of being formed by an Adaptive Sinusoidal Extruder Mechanism) have seen attention in recent years for their potential as structure and for energy harvesting. The behavior of these structures is, however, very sensitive to boundary conditions and initial geometry making their calibration for various applications difficult. The loop snap-through buckling behavior exhibited by sinusoidal assemblies during deployment may be an energy source ripe for piezoelectric energy harvesting. There is a need for novel assembly and deployment systems that incorporate computer-based control systems that can specifically modulate and possibly simulate a structure’s properties to reliably harness the potential energy of bistable structures.